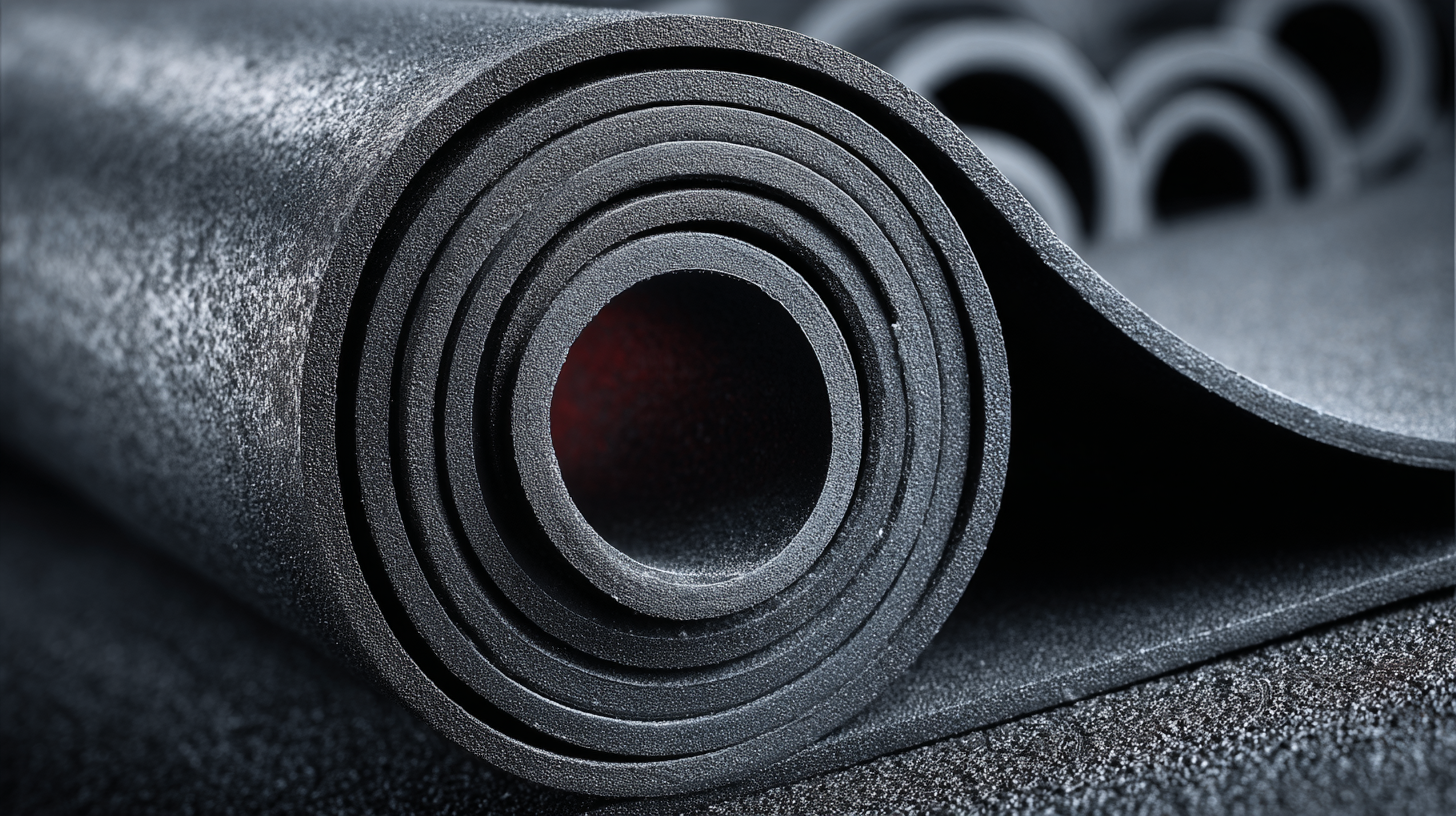

In the competitive landscape of manufacturing, identifying the best suppliers of Rubber Sheet is crucial for businesses seeking quality and durability in their products. According to market research by Grand View Research, the global rubber sheet market is expected to reach $25.47 billion by 2025, driven by rising demand from various industries including automotive, construction, and packaging. The increasing emphasis on sustainability and innovation in rubber production is reshaping industry standards, making it essential for companies to partner with manufacturers that not only meet these evolving benchmarks but also adhere to strict compliance protocols. This blog will delve into key factors to consider when evaluating potential manufacturers, providing insights drawn from industry reports and expert analyses to guide procurement decisions in this vital sector.

When selecting high-quality rubber sheets, it is essential to understand the manufacturing standards that govern their production. Quality standards play a pivotal role in ensuring the durability and performance of rubber sheets. Manufacturers that adhere to recognized standards create products that can withstand rigorous industrial applications. It is important to look for certifications that indicate compliance with international quality management systems and industry-specific benchmarks.

In the rubber industry, the application of quality tools—such as cause-and-effect diagrams—illustrates the importance of continuous improvement in manufacturing processes. For instance, analyzing production defects in processes like tire retreading can provide insights into quality control. Understanding how materials perform under operational stress can help manufacturers to refine their practices and produce superior rubber sheets. By focusing on these quality indicators, buyers can better identify reliable manufacturers and select the best rubber materials for their needs.

When it comes to selecting the best rubber sheets,

understanding the material types and their performance characteristics is crucial.

Different types of rubber, such as natural,

synthetic, and

reinforced rubber, exhibit varying levels of durability,

flexibility, and resistance to environmental factors.

For instance, natural rubber offers excellent elasticity and tensile strength, making it ideal for applications requiring high performance.

Conversely, synthetic rubbers can be tailored for specific properties, such as chemical resistance or temperature tolerance,

which can significantly affect the overall performance of the rubber sheets.

Choosing the right manufacturer is equally important,

as their expertise in material selection and processing can influence product quality.

Manufacturers that leverage advanced lightweight materials can provide rubber sheets that not only meet performance expectations

but also align with sustainability goals.

A growing consumer awareness regarding environmental impact

underscores the importance of choosing manufacturers committed to sustainable practices and responsible sourcing.

By carefully evaluating these factors, industries can enhance performance and ensure that the rubber sheets they utilize

contribute effectively to their operational needs.

When selecting a manufacturer for rubber sheets, evaluating their certifications and compliance standards is crucial. Certifications such as ISO 9001, which ensures a quality management system is in place, are essential indicators of a manufacturer’s commitment to quality and consistency. In fact, a recent industry report from the Rubber Manufacturers Association noted that certified manufacturers are 30% more likely to meet customer expectations compared to non-certified counterparts. Additionally, compliance with environmental standards, such as ISO 14001, indicates that the manufacturer is committed to sustainable practices, a growing demand in today’s market.

**Tip:** Always request a copy of the manufacturer’s certifications and assess their audit history. This will help you understand their adherence to voluntary and regulatory standards.

Moreover, compliance with industry-specific standards, such as ASTM D3935 for rubber sheets, can significantly affect product performance and longevity. Manufacturers that rigorously adhere to these standards reduce the risk of defects and ensure that their products are safe for various applications. According to a survey by the International Institute of Rubber Technology, nearly 85% of clients regarded compliance with industry standards as a top priority when selecting a rubber sheet supplier.

**Tip:** Look for testimonials or case studies that demonstrate the manufacturer’s reliability in meeting industry standards. This can provide insight into their track record and customer satisfaction levels.

When exploring how to identify top manufacturers for rubber sheets, one crucial aspect is analyzing customer reviews and market reputation. Reviews provide insightful feedback on product quality and durability, helping you gauge the experiences of previous buyers. Look for brands with consistent positive feedback, particularly regarding the material's performance in various applications. A strong reputation often correlates with expertise in manufacturing processes and customer service.

Tips for discerning reliable manufacturers include checking for certifications and industry affiliations. Accredited manufacturers are likely to adhere to higher standards, ensuring quality control and compliance with safety regulations. Additionally, don’t hesitate to reach out directly to manufacturers for inquiries about their practices and materials. Engaging with customer service can also reveal how they prioritize customer satisfaction.

Finally, it’s essential to analyze the overall market presence of a manufacturer. Companies that invest in branding, marketing, and extensive distribution channels typically have established themselves as leaders in their field. This visibility not only reflects trust from consumers but also indicates a commitment to product innovation and quality, pivotal qualities when selecting rubber sheet manufacturers.

When exploring innovations and technology in rubber sheet production, one cannot overlook the significant advancements that are shaping the industry. The integration of automated manufacturing processes is revolutionizing the way rubber sheets are produced, leading to higher precision and reduced waste. These technological enhancements not only improve the quality of the final product but also address environmental concerns by minimizing the ecological footprint of production.

To identify top manufacturers, consider the following tips: First, evaluate the company's investment in research and development. Manufacturers that prioritize innovation are more likely to offer advanced products that meet the evolving needs of their customers. Second, assess the range of materials and types of rubber sheets they offer. Top manufacturers continuously update their product lines to incorporate new materials, enhancing durability and performance.

Lastly, don’t forget to check for certifications and quality control measures. Reputable manufacturers adhere to strict industry standards, ensuring their products are safe and reliable. By focusing on these key factors, you can confidently identify leading manufacturers that leverage cutting-edge technology in rubber sheet production.