2025 How to Optimize Injection Mold Design for Better Efficiency and Cost Savings

The evolution of injection mold design has become paramount in driving efficiencies and cost savings across various manufacturing sectors. According to a recent report by the Plastics Industry Association, optimizing injection mold design can reduce production costs by up to 30%. This is significant for companies aiming to enhance their competitive edge while maintaining product quality. As the industry faces increasing demands for faster production cycles and customized solutions, a strategic approach to mold design is not merely beneficial but essential.

Expert opinions underscore the importance of innovative design practices. Dr. Emily Carter, a renowned authority in injection molding technology, asserts, "An efficient injection mold design not only minimizes material waste but also streamlines the production process, allowing manufacturers to respond swiftly to market changes." Her insights reflect the broader trend of integrating advanced technologies like CAD and simulation software into mold design, further optimizing performance and reducing lead times.

As businesses strive to align with sustainability goals and improve profitability, investing in cutting-edge injection mold design techniques emerges as a critical strategy. The potential for heightened efficiency and substantial cost savings positions injection molding as a focal point for manufacturers looking to thrive in a competitive landscape.

Understanding Injection Mold Design Principles for Efficiency

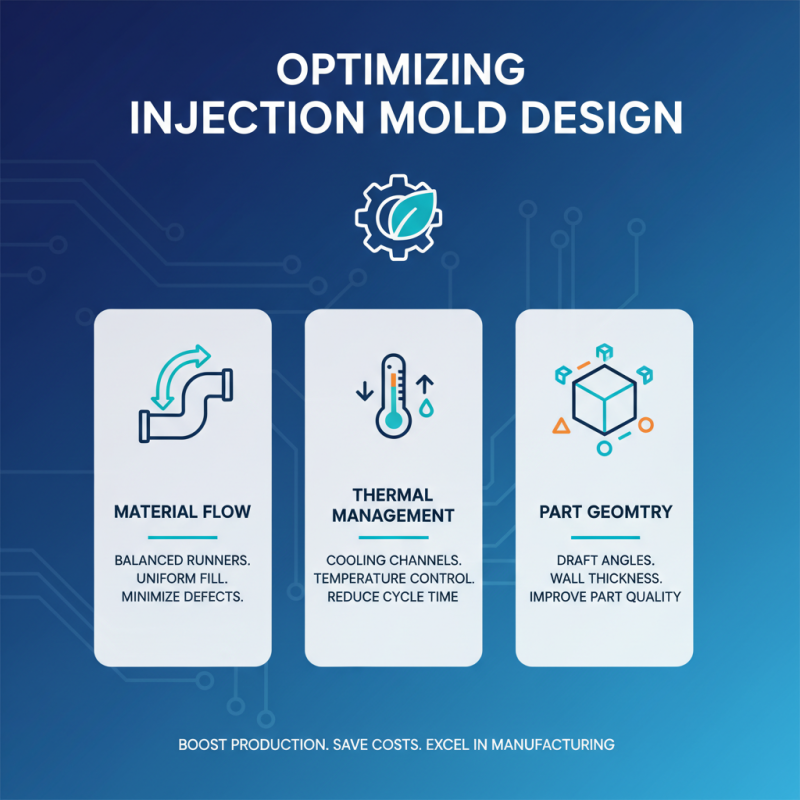

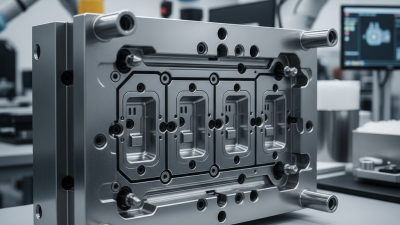

Understanding the principles of injection mold design is crucial for optimizing production efficiency and achieving significant cost savings. A well-designed mold not only reduces cycle times but also enhances the quality of the produced parts. Key principles include considering material flow, thermal management, and part geometry. Ensuring that the injection mold allows for balanced flow of the molten material minimizes defects and improves the overall aesthetic and structural integrity of the final product.

Tips: Always start by analyzing the geometry of the part being produced. Keep the design as simple as possible; complex shapes can lead to difficulties in the molding process. Additionally, focus on the cooling system of the mold, as effective cooling can drastically reduce cycle times and energy consumption, thus lowering costs in the long run.

Another vital principle is incorporating tolerances and fits early in the design phase. By understanding the manufacturing capabilities and selecting proper tolerances for various features, designers can eliminate costly rework and adjustments later in the production process. This foresight not only improves efficiency but also boosts the profitability of the overall project.

Tips: Utilize simulation software to predict how the mold will perform under various conditions. This allows for adjustments to be made prior to production, saving time and resources while ensuring that the final product meets quality standards.

Key Factors Influencing Injection Mold Design Optimization

Optimizing injection mold design is crucial for enhancing production efficiency and achieving cost savings. Several key factors play a significant role in this optimization process. One of the primary considerations is the material selection for both the mold itself and the product. Studies indicate that choosing the right materials can reduce molding cycle times by up to 30%, leading to faster production rates and lower costs. Additionally, the design complexity directly impacts the manufacturing process; simpler designs typically reduce lead times and labor costs.

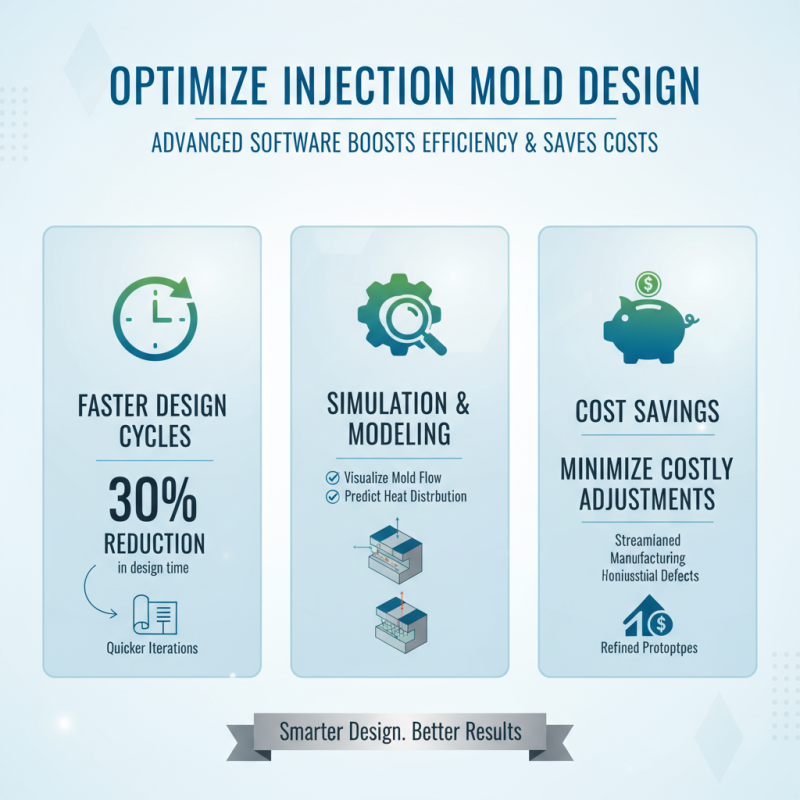

Another factor is the incorporation of advanced technologies, such as computer-aided design (CAD) and simulation tools. These technologies allow engineers to predict potential issues and optimize flow dynamics before physical production begins. A recent report highlighted that companies employing simulation tools experienced a 25% reduction in the number of design iterations, ultimately saving both time and resources.

Tip: Implementing a standardized process for mold design can significantly reduce development time. Establishing guidelines for common part designs can streamline workflow and enhance collaboration among design teams.

Tip: Regularly reviewing and updating design practices based on industry advancements can keep your processes efficient. Staying informed on the latest technologies and materials ensures that your mold designs are competitive and cost-effective.

Techniques for Reducing Production Costs in Injection Molding

Optimizing injection mold design is crucial for reducing production costs and enhancing efficiency in manufacturing processes. One effective technique is the use of advanced simulation software during the design phase. This software allows engineers to predict the flow of molten plastic, identify potential defects, and optimize cooling channels before the physical mold is created. By conducting simulations, manufacturers can significantly decrease trial-and-error costs associated with mold adjustments, ultimately leading to faster production times and less material waste.

Another strategy involves selecting the right materials for both the molds and the injected products. Utilizing high-performance yet cost-effective materials can lead to improved durability and reduced wear on the mold, which translates to lower maintenance costs. Additionally, incorporating design features such as self-lubricating surfaces or enhanced cooling systems can optimize cycle times, further driving down production costs. Ultimately, the combination of advanced design techniques and material selection can result in a more efficient injection molding process, helping manufacturers stay competitive in a rapidly evolving market.

2025 How to Optimize Injection Mold Design for Better Efficiency and Cost Savings

| Optimization Technique | Impact on Efficiency (%) | Cost Reduction ($) | Implementation Difficulty (1-5) |

|---|---|---|---|

| Improved Cooling Channel Design | 20 | 5000 | 3 |

| Enhanced Material Selection | 15 | 3000 | 4 |

| Mold Flow Analysis | 25 | 7000 | 2 |

| Cycle Time Optimization | 30 | 8000 | 2 |

| Reduction of Ejector Marks | 10 | 2000 | 3 |

Materials Selection for Enhanced Mold Performance and Longevity

When it comes to optimizing injection mold design for enhanced performance and longevity, material selection plays a crucial role. The right materials can significantly improve the mold's durability and efficiency, thereby contributing to overall cost savings in production. For instance, utilizing high-quality steel alloys that offer both strength and corrosion resistance can minimize wear and extend the mold's lifespan. Additionally, the choice of surface coating can protect against abrasion and thermal wear, ensuring that the mold maintains its precision over many cycles.

Tips: Consider using materials with excellent thermal conductivity to reduce cycle times and enhance cooling efficiency. Incorporating features such as conformal cooling channels can also improve heat dissipation and ensure even cooling of the injected materials, ultimately leading to better part quality.

Another factor to keep in mind is the compatibility of the material with the specific application. For instance, certain polymers may require molds made from materials that are designed to withstand higher temperatures or chemical exposure. Evaluating the unique demands of the intended use can guide the selection process, allowing for an optimal balance between performance and cost efficiency.

Tips: Always assess the total lifecycle costs of the materials being considered, including maintenance and replacement costs. A slightly higher initial investment in a superior material can yield significant long-term savings by reducing downtime and production interruptions.

Evaluating Design Software Tools for Optimal Injection Mold Solutions

In the pursuit of optimizing injection mold design, leveraging advanced design software tools is crucial for enhancing efficiency and achieving significant cost savings. Recent industry reports indicate that the integration of simulation and modeling software can reduce the design cycle time by up to 30%, allowing for quicker iterations and more refined prototypes. These tools enable engineers to visualize mold flow, heat distribution, and potential defects before physical production begins, which minimizes costly adjustments and streamlines the overall manufacturing process.

Moreover, the application of design software that incorporates artificial intelligence (AI) has been shown to further advance mold design. According to data from the Injection Molding Association, firms that utilize AI-driven software solutions report a 20% reduction in material waste and a 15% increase in overall production efficiency. With such capabilities, engineers can identify optimal designs that not only speed up production but also enhance the durability and performance of the molds. By prioritizing the evaluation and integration of these software tools, businesses can cultivate a more competitive edge in the rapidly evolving landscape of injection molding.

Related Posts

-

Exploring Opportunities for Injection Molded Parts at the 2025 China 138th Import and Export Fair

-

Top 10 Tips for Injection Mold Design: Achieve Optimal Efficiency & Quality

-

Exploring Innovations in Plastic Extrusion at the 138th Canton Fair 2025: Industry Insights and Trends

-

Understanding the Future of Injection Molding Materials: Innovations and Trends You Need to Know

-

Impact of Injection Molding Cost Trends on Businesses Exhibiting at the 138th Canton Fair 2025

-

Revolutionizing Production: The Future of Molding Machines in Advanced Manufacturing